Westfield Fasteners Product Specification:

DIN 3021 - Spring band clamp

This product guide contains the specification for Spring Band Clamps, a series of standard parts available from Westfield Fasteners. The basis of this specification is the internationally recognised DIN standard DIN 3021.

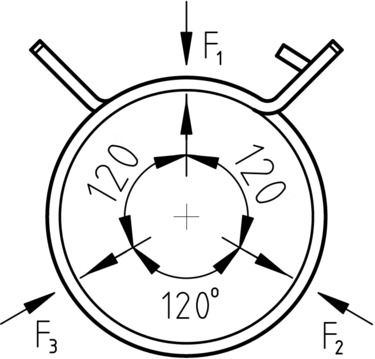

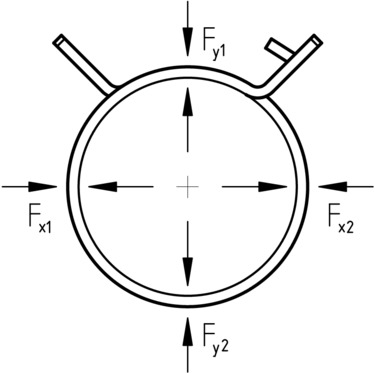

Spring band clamps are a one piece, bolt free hose clamp made from hardened spring steel. They are designed to be used with hose systems where temperatures can fluctuate significantly. The shape of the spring band clamp will allow the clamp to continue to apply an even and consistent radial clamping force, within a temperature range of -40°C to +120°C. These spring band clamps are suitable for heavy duty applications.

The clamp is opened by squeezing the two ears together. This can be done with pliers or there are specific tools available. The steel clamps are finished with layers of a black chrome (Vl) free coating, which contains zinc.

Scope of the DIN Standard

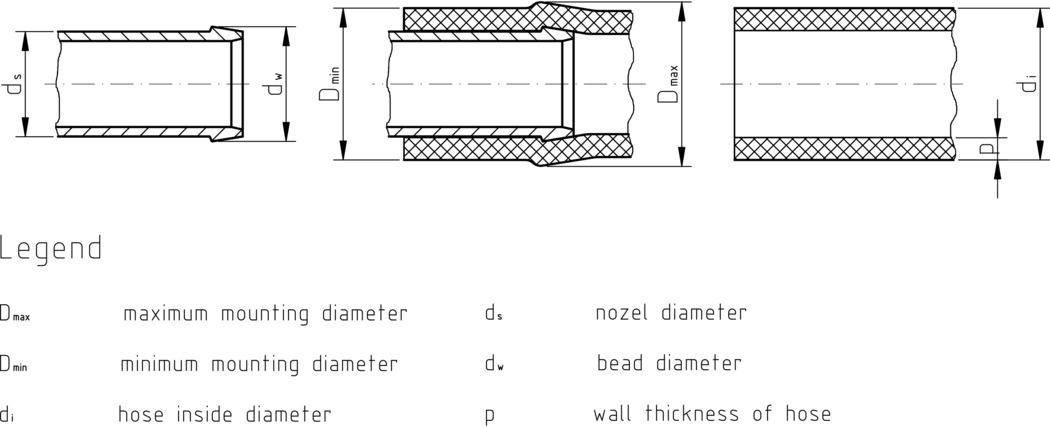

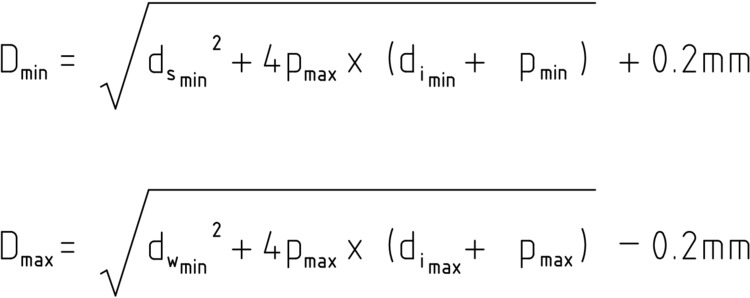

DIN 3021 specifies the characteristics for this spring band clamp design, made from hardened spring steel for sizes from 13mm to 90mm in diameter. The diameter given (nominal diameter) is the optimum hose outside diameter. The nominal diameter will not be equivalent to the diameter shipped.

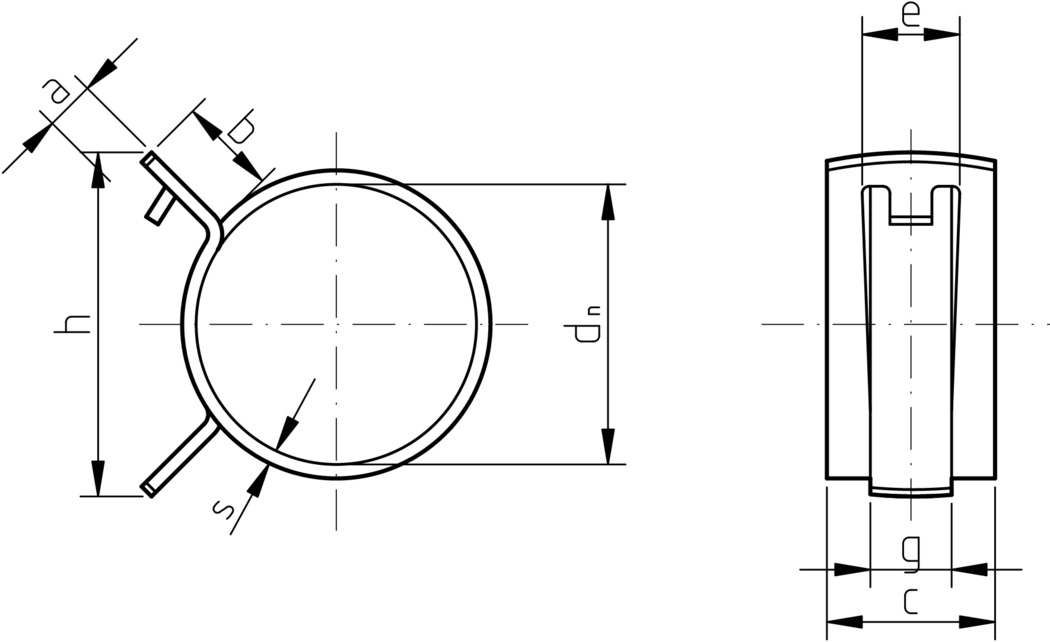

Table 1, with figure 1 gives part dimensions and relevant tolerances. Table 2 gives the 3 directional clamping forces of each clip, whilst table 3 gives the same forces in 4 directions.