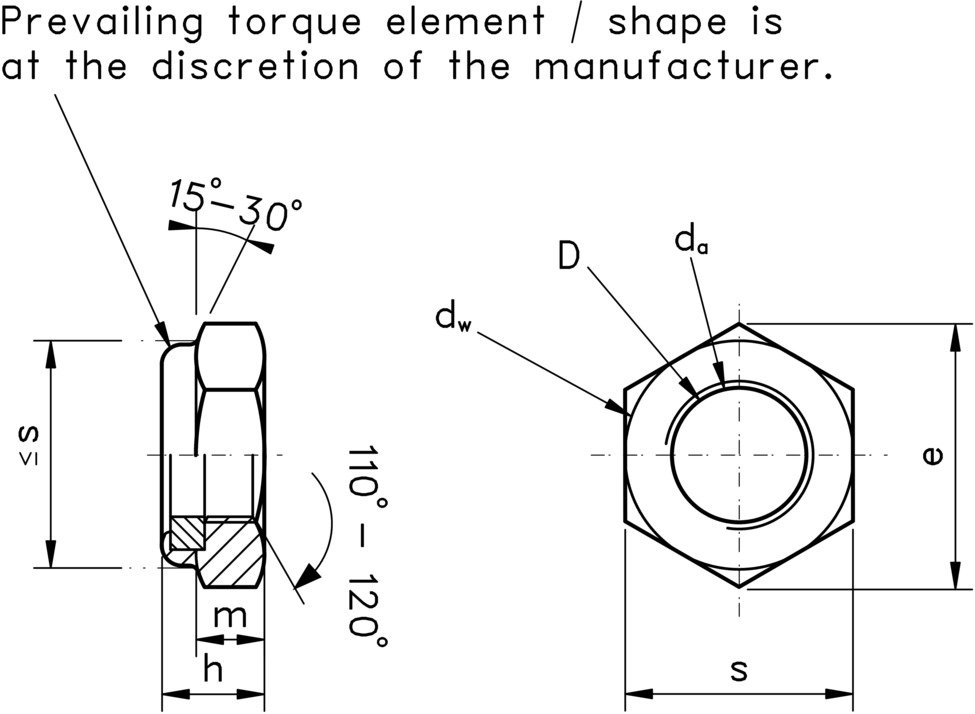

DIN 985 - Nyloc Nuts, Low or Thin Type (Type T)

This product guide contains the specification for metric threaded low type nyloc nuts, a range of standard parts available from Westfield Fasteners. The basis of this specification is the DIN standard DIN 985.

DIN 985 mentions steel as a material with property classes 8 and 10. It does not mention stainless steel or brass, but the dimensions will be the same.

Table 1 below defines the overall dimensions and tolerances of this nut type.

Although the DIN 985 standard has now been superceded by ISO 10511, off the shelf parts are currently more generally available to the older specification. The ISO standard specifies revised nut heights and across the flats dimensions on certain sizes, but are otherwise interchangable.