Westfield Fasteners Product Specification:

ISO 10642 - Hexagonal Socket Head Countersunk Screws

This product guide contains the specification for metric threaded socket head countersunk screws as available from Westfield Fasteners. The basis of this specification is the ISO standard ISO 10642, which replaced the original standard DIN 7991. The specification outlined below may include information on sizes and materials that are not covered by the ISO standard but are available.

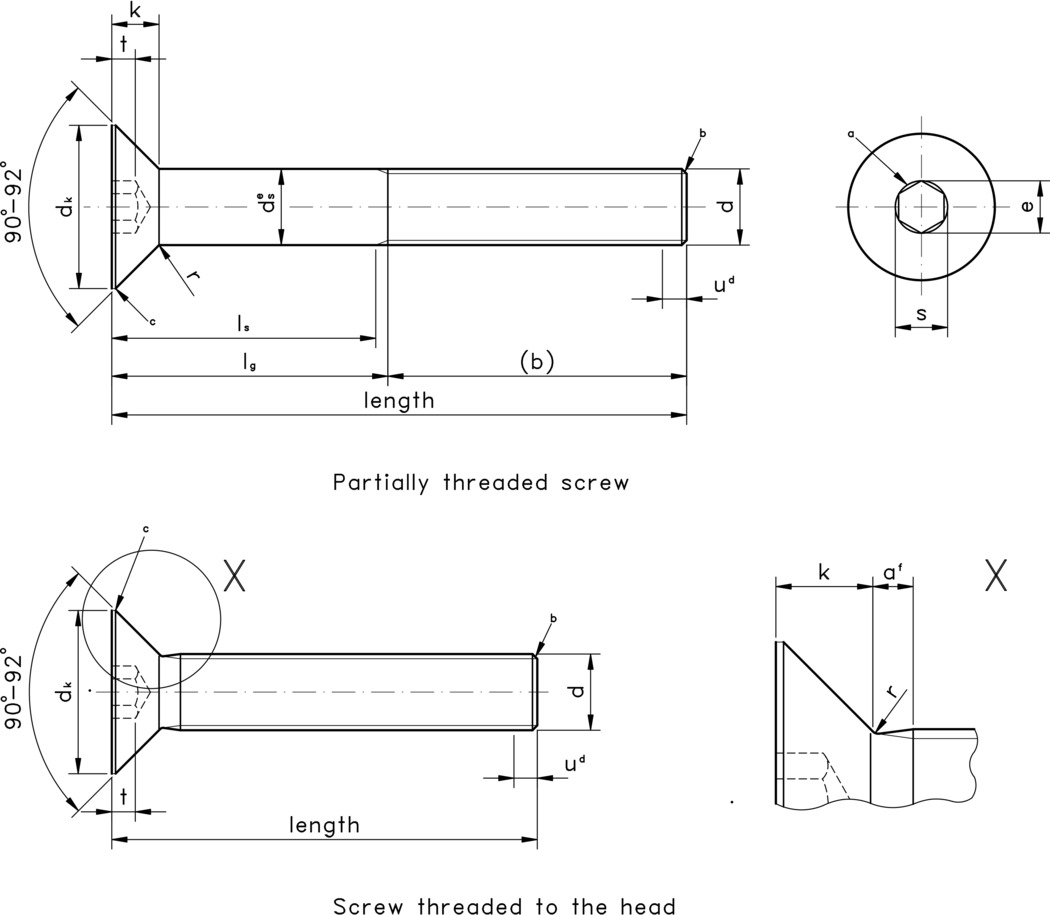

A countersunk headed screw conforming with ISO 10642, requiring a hex key (otherwise known as an Allen key) to fit. The countersunk head is used in conjunction with a countersunk hole to provide a flush, snag free fit. Generally manufactured with a full thread, though occasionally some stock may include a partially threaded shank. The head diameter is slightly larger than that of the equivalent DIN 965 Phillips or Pozi driven screw.

Scope of the ISO standard.

ISO 10642 specifies the tolerances and the permissable variation in form of hexagon socket countersunk head screws, and covers metric thread diameters from M2 up to and including M20. Mechanical properties for these items are defined in ISO 898 and ISO 3506. Table 1 below defines the overall dimensions and tolerances of this screw type. Table 2 defines the tolerances on the shank length. Due to their head design socket countersunk screws are considered to have reduced loadability over other screw types, as defined in ISO 898 and ISO 3506.