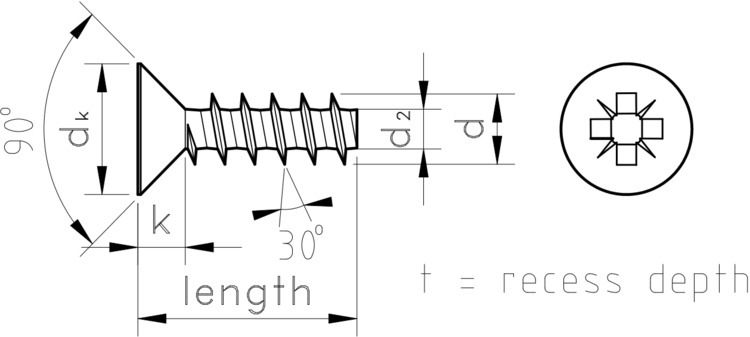

Thread Forming Screws for Plastics - Pozi Countersunk with 30° Thread Angle

This product guide contains the specification for thread forming screws for plastics, a series of standard parts available from Westfield Fasteners. The information presented here is specific to products with a pozi countersunk head and a 30° thread angle.

These thread forming screws have a 30 degree thread angle to optimise performance in all types of thermoplastics. Correctly used these screws will minimise the stress to the plastic and give optimal thread engagement and clamping loads.

Thread forming screws deform the plastic around the thread as they are inserted. This gives an optimum fastening force, which is superior to standard self-tappers. The narrow thread profile increases the pull out resistance and gives lower radial stress. The lower radial stress also prevents boss damage.

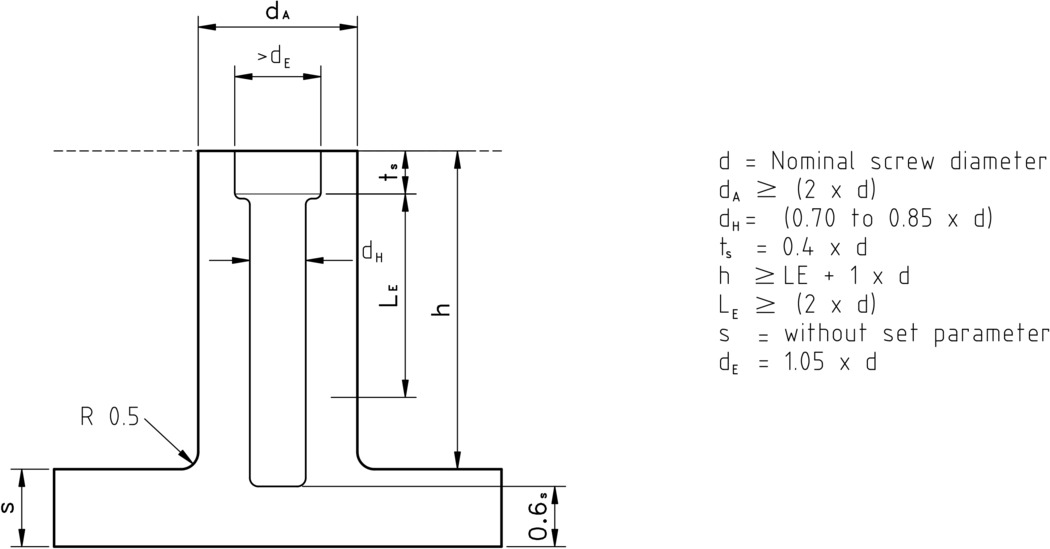

Please see figure 2 and table 2 for the recommended pilot pre-drilled or moulded holes required for different plastics.

- Pilot holes should ideally be chamfered (or have a counterbore) to the thread major diameter to prevent cracking.

- Boss heights should be constructed so that there is no gap between the top of the boss and the component being clamped.

- Boss diameters should be approximately 2.5 to 3 times the diameter of the pilot hole.

- The stripping torque to tapping torque ratio should be at least 3-1 or around 5-1 for automated high volume manufacturing.

- Pilot holes should have a threaded engagement of at least twice the screw diameter.

- Specific application testing is advisable where there is uncertainty of type and size.